|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

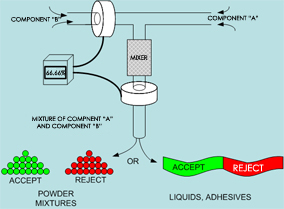

Two component adhesives such as resin, catalyst have relied on the “Dixie Cup Test” since dispensing first began. Once a shift, an operator turns off the dispensing equipment for about 15 minutes, removes the mixing tube, and starts the “Dixie Cup Test”. The intent is to confirm the dispensing equipment is providing the correct mix ratio. The Components are dispensed prior to being mixed. As the mixing head hangs in air a dixie cup is awkwardly squeezed under each outlet hoping to avoid spillage. A second operator enters a manual dispense mode filling the dixie cups. The two cups are weighed and the mix ratios are “calculated“. But what is being measured? How does weighing materials equate to the accuracy of a mixture? It doesn’t!

Click to here to view article in PDF format (Adobe Reader required)

|

|||||

|

|||||

PATENTED AND PATENTS PENDING.

Click to here to view article in PDF format (Adobe Reader required)

|

|||||

|

|||||

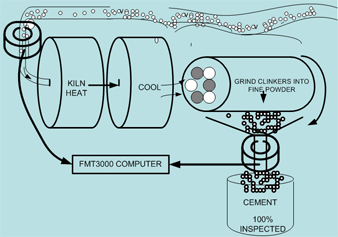

Patented and patents pending: Ford Motor Co., Real Time Ware, Inc.

Click to here to view article in PDF format (Adobe Reader required)

|

|||||

|

|||||

Missing threads are rejected! Quartz accuracy and high power are combined to drive low cost non-contact sensors. The module is a complete thread detection system with digital display, accept/reject limits and solid state relay. Excellent stability over extreme environmental conditions make THREAD-CHEK 2000M ideal for rejection of missing threads on the production line. Modularity makes expansion and serviceability easy.

Click to here to view article in PDF format (Adobe Reader required)

|

|||||

|

|||||

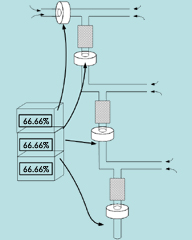

Real Time Ware was selected by Ford Motor Company to extend the use of this patented process throughout industry, and has been awarded worldwide exclusive rights. We are interested in automotive and non-automotive uses that require accurate mixing and can apply our patented technology to meet the needs of your particular mixing problems.

Click to here to view article in PDF format (Adobe Reader required)

|

|||||

|

|